Contact us about your Filter Press Requirements!

Brief description of the Filter Pressing process

Slurry is pumped into the Filter Press by either using slurry pumps or by means of gravity feeding the filter press. The solids accumulate in the filter plate cavities between the filter cloths and the water is discharged through filtrate ports. The accumulated mud in the cavities will form cakes. These cakes will be discharged from the Filter press by opening the cavities..

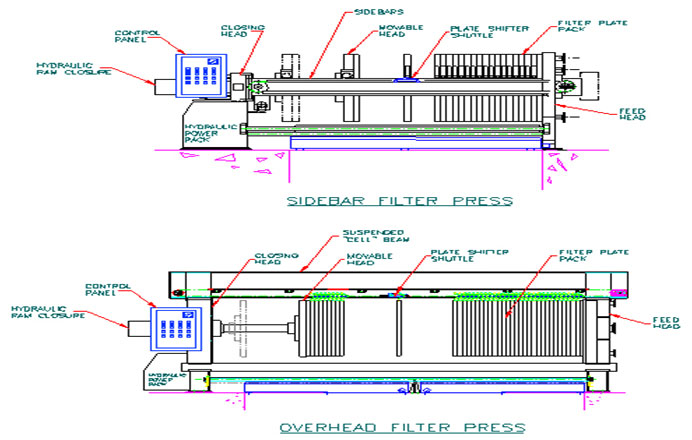

TWO TYPICAL TYPES OF FILTER PRESSES

1. Full Description of the Process

The Filter Press consists of a number of chamber filter plates mounted vertically on and between two sidebars. The side bars are connected at one end to fixed head (end plate) or feed head and the other end to a closing head. Through a closing arrangement on the head, usually a hydraulic ram (push plate), the filter plate pack is compressed tightly together between the end plate and push plate, thus forming filtering unit. (See figure 1 page 7)

The filter cake chambers are formed by mating two recessed chamber plates. The two faces of the filter plate have a drainage surface in the form of ribs, grooves or

pipes to allow filtrate (water) to drain behind the cloth to the drainage port s located in each corner of the filter plates. These ports, in turn connect to the corner eyes, which carry the filtrate (water) drainage to the fixed end (end plate) of the filter press.

A filter cloth is mounted over each of the two faces of the filter plate.

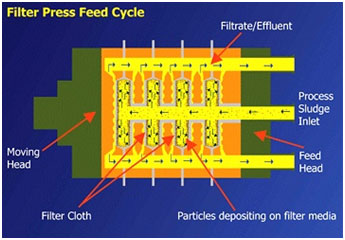

Filter Press Feed Cycle – (Figure 1&2)

Figure 1

Figure 2

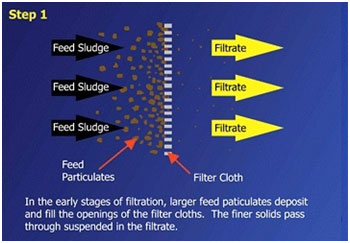

Step 1 (Figure 3)

Slurry is fed into the press by a suitable pumping system or gravity feed and passes through the feed eye of the succeeding plates along the length of the plate pack unit until all chambers are full of mud/slurry.

Figure 3

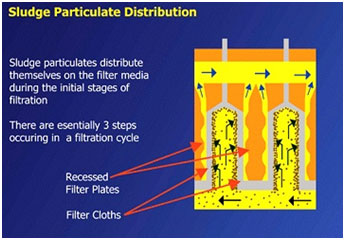

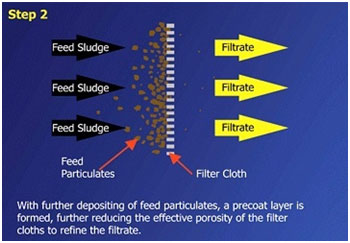

Step 2 (Figure 4)

Solid particles begin to deposit on the surface of the filter cloth forming the initial layer of filter cake (referred to as the pre-coat). Once applied, this initial layer becomes the actual filtration medium. During this process the filtrate (water) that is discharged may still not be clean and clear. As soon as the initial layer (pre-coat) is completely covering the filter cloth, the water will become clear and clean.

Figure 4

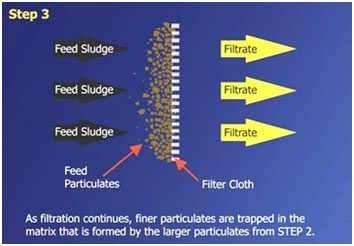

Step 3 (Figure 5 & 6)

As the filtering process continues the cake thickness gradually increases until the chamber is completely filled. At this point of the cycle, the dewatering phase enters into the final cake consolidation process to achieve maximum cake dryness.

Figure 5

Figure 6

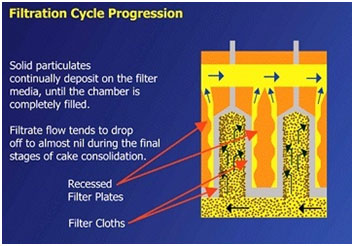

Final Cake Consolidation (Figure 7)

During the consolidation step of the cycle, additional solids are being pumped into the filter chamber to displace more liquid. The result is a dryer and denser cake.

This cycle normally continues until filtrate (water) flow from the mud press is reduced to virtually nil. At this point, the feed pump is stopped or the gravity feed pipe line closed off and the internal pressure within the filter plate pack is relieved.

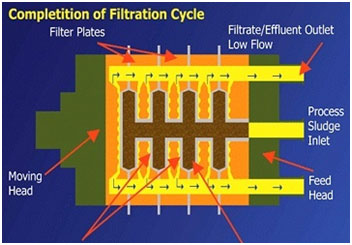

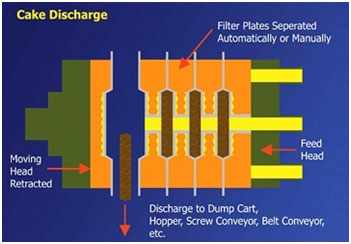

With pressure relieved, the hydraulic closure system is activated to retract the push plate (moving head) to its fully open position.

Once opened, the filter plates are individually separated from each other, allowing the mud cakes to fall freely from between the separated chambers. (Figure 8) Depending upon the size of the press or the system in place, the plates may be moved manually or by a semi or fully mechanized plate shifting device / system.

After the filter cakes have been fully discharged the press cycle is completed.

Normally the Hydraulic system will be shut off after the push plate is in fully open position and during the discharge process.

The mud cakes may be discharged on to a conveyor belt system under the mud filter press or directly into an ore pass system or on to deflection plates to drop material at the side of the press or directly under the press. If dropped at the side or directly under the press it is usually removed by means of a Front End Loader and loaded.

Figure 7

Figure 8